Thermofin’s range of industrial air cooled heat exchangers is meant to address the particular needs of applications featuring necessary atmospheric discharges. It is perfectly adapted to cooling industrial processes as varied as those of the energy sector, petrochemical plants, the environment industry, metal mills, pulp and paper industry, plastics plants, the agrobusiness and others. The custom design of the industrial air cooled heat exchanger is optimized to respond to the particular needs of your application.

PERFORMANCE AT ALL LEVELS

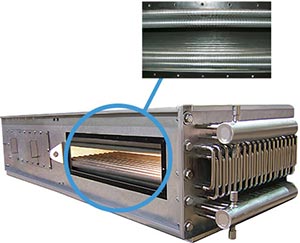

ALUMINUM EXTRUDED FINNED TUBES

Thanks to the use of aluminium extruded fin tubes, the industrial air cooled heat exchangers are less likely to be affected by higher fouling environments. Fouling is the main source of lower efficiency for aging equipment. In effect, this finning technology prevents the external air, which may be carrying various impurities (pollution, pollen, dust, particulates, …), from entering in direct contact with the liner tubes. Neither such impurities nor corrosion can lodge itself between the fins and the liner tube, allowing the air cooled exchanger to retain its efficient heat transfer characteristics throughout the years. Aluminium extruded fin tubes also permit rapid and efficient cleaning of the fins with the use of high pressure water jets, their thickness and sturdy construction protecting them from deformation.

QUALITY CONSTRUCTION

Built with heavy gauge painted steel, galvanized steel or stainless steel, the casing and structure of Thermofin’s industrial exchangers has been designed for durability and longevity.

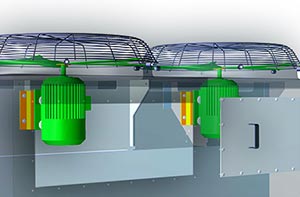

INDUSTRIAL GRADE MOTORS

Thermofin’s study of the latest development in air handling has also yielded highly efficient custom designs of the fan motor arrangement, insuring optimum performance at the electrical, acoustic and flow distribution levels. Custom designs also means that the EOLIA industrial air cooled heat exchanger meet or exceed your requirements notably by the use of high efficiency electric motors and axial type low noise fans.

- All motors are of industrial quality and at least TEFC, explosion proof motors are available for even more rugged environment or to meet other security requirements. Fan propeller material is also selected with site constraints in mind (propellers of reinforced nylon or polypropylene for corrosive environments, aluminium propellers for explosive environments, etc.)

- Variable speed motors may be installed on Thermofin Air Cooled Heat Exchangers to allow for modulating cooling capacities and for a reduction in energy consumption.

- The electrical installation, along with the electrical components, can be designed and selected to meet or exceed market standards such as C.S.A. or U.L.

MANY OPTIONS AVAILABLE

Thermofin is keenly aware that the equipment maintenance and proper operation play a key role in the perfomance and longer life expectancy of the industrial air cooled heat exchangers. Consequently, Thermofin has developped various options to facilitate and to shorten the time associated to these activities

- Addition of access doors to facilitate electrical motor maintenance.

- Middle access between tube rows to permit efficient and fast cleaning of finned surfaces.

- Easy access to electrical junction box.

- Addition of pollen filters to prevent seasonal or environmental clogging of fins.

- Addition of ladders and guardrails.

Various coatings are also available based on the localised requirements of the site installation (special paints, « Heresite » coating, hot galvanizing, etc.)

Many material choices are also available to meet your needs.

A large selection of connection types : Flanged, NPT, Victaulic, etc.

You are an agent interested in selling our products, or you are simply looking for additional information? Don’t hesitate to download our brochures. We can also provide, upon request, prints & other promotional material.