At a time when we talk more and more about the environment and rationalization of energy use, thermal energy storage represents a technical solution adapted to industrial cooling and air conditioning systems. Office building cooling loads often peak at a level two or more times higher than the daily 24-h average load. Some industrial processes also have load peaks or “spikes”; that rise much higher than the average load. In addition, many electric utilities impose demand charges based on the customer’s highest power demand during on-peak hours and/or during the entire billing cycle. The STL is an ideal and efficient solution for these applications.

Traditional refrigeration systems are designed to satisfy the peak cooling demand, which occurs only a few hours per year, and thus spend their operational life working at reduced capacity and low efficiency. The STL, which is suitable for any air-conditioning system or refrigeration plant, allows installed chiller capacity (and size of other components) to be significantly reduced – typically between 40 and 60%. The STL thermal energy storage system provides the shortfall of the energy when demand is higher than the chiller capacity. Thus chiller operation is continuous and its efficiency is at a maximum. This is the most effective way to reduce operating costs of process refrigeration and building air-conditioning and to take advantage of lower cost off-peak electricity and to reduce the demand charge by reducing the required electrical supply. The STL allows real management of the cooling energy according to the demand.

The reduction in the chiller size also reduces the quantity of refrigerant used, a point that is more and more important with the new restrictive laws on refrigerants. In addition, the STL allows the consumption of night-time electricity produced with a higher efficiency (2 300 kcal/kWh compared to 3500-4000 kcal/kWh at peak hours). The result is a reduction of CO2 emissions and a saving of energy.

THE STL TECHNOLOGY

STL

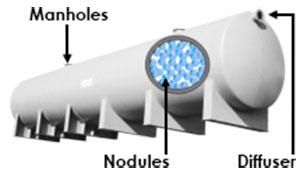

Latent heat thermal energy storage allows a very high energy density (6 to 12 times more important than sensitive storage energy). Storage volume and thermal losses are greatly reduced. The STL is composed of a tank filled with nodules (balls) and heat transfer fluid. The nodules take up approximately 60% of the tank volume, the 40% remaining being occupied by the fluid. The number of nodules in a system determines both the heat exchange rate between the nodules and the heat transfer fluid and also the total energy stored in the STL.

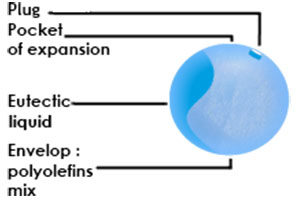

Nodules

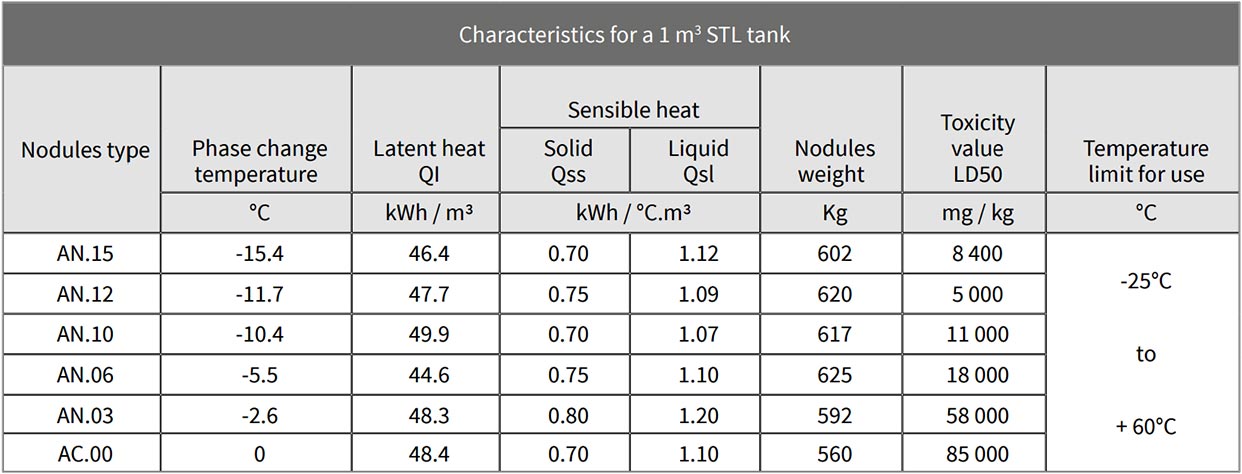

The spherical nodules (balls) are blow moulded from a blend of polyolefins and filled with PCM (Phase Change Material). A range of PCMs allows thermal energy to be stored at temperatures between -33°C and +27°C. The 98 mm diameter nodules (nodules AC and AN) are made for applications at low temperatures of -2.6 to -15°C and air conditioning systems at 0°C. In addition to its outstanding thermal performance in terms of exchange capacity, CRISTOPIA’s nodules have a long lifespan, the equivalent of 30 to 40 years of use under normal conditions.

Nodule characteristics

- Material: blend of polyolefins

- Chemical neutrality regarding PCM and heat transfer fluids

- Thickness greater than 1 mm: no migration of the heat transfer fluid

- Sphere obtained by blow moulding: no leaks

- Ultrasonic welding of the cap

- Expansion reserve: reduced enveloppe stress

- Lifespan equivalent to 30-40 years of use under normal conditions

- Recyclable

A MEG or MPG heat transfer fluid

The heat transfer fluid of the thermal energy storage nodules is made of water and mono ethylene glycol (MEG) or water and mono-propylene glycol (MPG). MEG or MPG concentration varies with the phase change temperature of the nodule.

The expertise of Cristopia on phase change materials

CRISTOPIA has a unique expertise on Phase Change Materials (PCM), the results of more than 30 years of R&D in partnership with technical centres and universities in France and in Europe. We have worked on all types of PCM (solid liquid transition) over a wide range temperatures of -64°C to +120°C: inorganic materials (hydrated salts) and organic materials (paraffins and fatty acids or bio PCM). Our expertise focuses on PCM (formulation, nucleation, characterization, durability, recyclability,…) on the packaging and encapsulation of PCM, on encapsulation materials (compatibility between materials, ageing,…), on industrial manufacturing processes and the engineering of the thermal energy storage system with PCM.

A custom made tank

The heat exchange between the nodules and the thermal energy storage system is done by means of the heat transfer fluid within the tank. The tank dimensions are calculated according to the installation and STL capacity. The tank may be cylindrical (black steel), resisting pressures up to 10 bar, or rectangular (concrete or steel) for atmospheric service pressure. Cylindrical tanks can be horizeontal, vertical, installed indoors, outdoors or buried.

The heat exchange between the nodules and the thermal energy storage system is done by means of the heat transfer fluid within the tank. The tank dimensions are calculated according to the installation and STL capacity. The tank may be cylindrical (black steel), resisting pressures up to 10 bar, or rectangular (concrete or steel) for atmospheric service pressure. Cylindrical tanks can be horizeontal, vertical, installed indoors, outdoors or buried.

What you need to know about the technology

- A solution which allows to manage important energy cooling needs for air-conditioning and industrial cooling.

- Many benefits such as up to 70% reduction in installed chiller capacity, the use of electricity at the lowest prices, and management of the cooling production based on actual needs.

- The STL is composed of a tank filled with nodules and heat transfer fluid (mixture of water and mono-ethylene glycol and water or mono-propylene glycol). MEG or MPG concentration varies with the phase change temperature of the nodule.

OPERATION MODES OF OUR THERMAL ENERGY STORAGE SOLUTION

The hydraulic layout depends on technical criteria as the difference between leaving and return temperatures (ΔT) and STL strategies used (operating modes),…and economic criteria as investment and operating costs optimization. Below are 4 basic hydraulic layouts used for air-conditioning installation and industrial refrigeration. We choose and adapt the hydraulic system during the engineering phase to meet the needs of our customers.

What you need to know about the system operation

- The parallel layout with a 3-way valve gives a great flexibility while piloting the installation.

- The variable flow layout limits the pumps consumption and increases the energy efficiency of the installation.

- The downstream or upstream series layout allows to operate with a high ΔT and to give priority on both operatings and investment costs savings.

WHY STL

An essential and unique technology for air-conditioning and industrial cooling

Air conditioning systems (HVAC) are traditionally designed to satisfy needs on the hottest days of the years. Industrial refrigeration systems often supply cooling energy for short high consumption periods (corresponding to production cycles). These systems are designed to meet peak demand but they rarely operate at their nominal capacity and are often on hold for several hours. When cooling need are regulated (with peak and off-peak hours), it is particularly advantageous to use CRISTOPIA thermal energy storage STL to spread the production time over a longer period.

To make both energy and operating costs savings

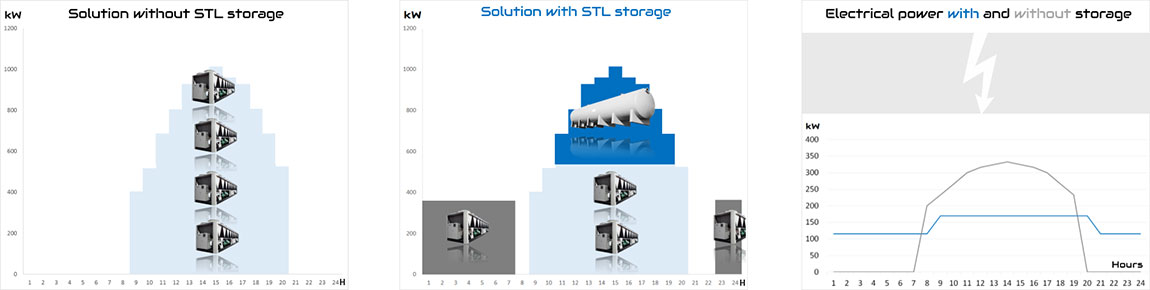

The STL is a thermal energy storage system by latent heat with high energy performance. By spreading the thermal energy production over 24 hours, STL can reduce the capacity of the chillers by 30 to 70%. It can also reduce the electricity power by 30 to 80% depending on chiller technology. The STL stores energy during the cheapest periods (off peakà and releases it during the most expensive periods (peak hours). By transferring electricity consumption to times when electricity prices are most advantageous, significant savings on electricity costs can be made.

Histogram of a building's cooling demand and its daily electricity consumption

The STL reduces the size of the installation by 30 to 70%. The example above shows that, thanks to the Cristopia thermal energy storage, the number of machines needed for the cooling production dropped from 4 to 2, with a 50% power reduction. By storing thermal energy during the night to release it during the day, this solution allows to use of electricity at the lowest prices and avoids the peaks.

STL's thermal energy storage advantages

To reduce :

- chiller size: by 30 to 70%

- the amount of refrigeration fluid

- the size of the cooling towers or dry coolers

- the electricity power: by 30 to 80%

- noise pollution

- ON / OFF of the chiller

- maintenance costs

- operating costs.

To increase :

- the cooling capacity of the installation

- energy efficiency of chillers

- regularity of the electrical load profile

- performance and reliability of the installation

- lifespan of the system

- flexibility of the system

- energy management

What you need to know about the STL

- The STL allows to store thermal energy when electricity is less expensive.

- It regulates the cooling production by discharging the energy (accumulated at night) when electricity is the most expensive.

- It allows to reduce the electricity power of the air-conditioning and industrial cooling by 30 to 70%.

- It allows to reduce operating costs, maintenance costs and the electrical power of the system with transfer to off-peak hours.

MARKETS / INDUSTRIES

A system suitable for any application

CRISTOPIA STL adapts to any type of application of the cooling production and integrates easily with existing installations. CRISTOPIA offers thermal energy storage (TES) solutions corresponding to their customer’s needs (leaving temperature, capacity and cooling load request, etc.). Depending on market needs, air-conditioning (HVAC), industrial refrigeration or backup facility, we choose the right solution to provide operating economy with energy efficiency and thermal comfort within buildings.

Air-conditioning

- Hôpitaux

- Hospitals

- Shopping mall

- Office buildings

- Data center

- Education

- Airports

- Sports & Entertainment

- Hotels

- Public institutions…

Rescue facilities

- Data centers

- Cleanrooms

- Call centers

- Hospitals…

Industrial cooling

- Food industries

- Pharmaceutical industries

- Slaughterhouses

- Refrigerated warehouses

- Bottling plants

- Dairy industries

- Power plants

- Breweries

- Ice rinks …

You are an agent interested in selling our products, or you are simply looking for additional information? Don’t hesitate to download our brochures. We can also provide, upon request, prints & other promotional material.