THE UNIVERSAL EXCHANGER

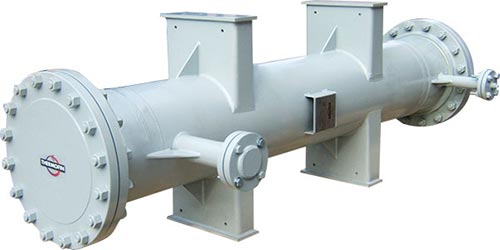

The physico-chemical properties, the phases (liquid, gaseous or solid) and the corrosivity of the fluids involved in industrial processes are extremely varied. The heating or cooling of such fluids requires a flexible and efficient exchanger technology. The standardized exchangers cannot meet all the constraints present in these very particular processes. The Thermofin shell & tube heat exchangers are custom-made, thus integrating many specific features to perfectly meet your needs.

DETAIL

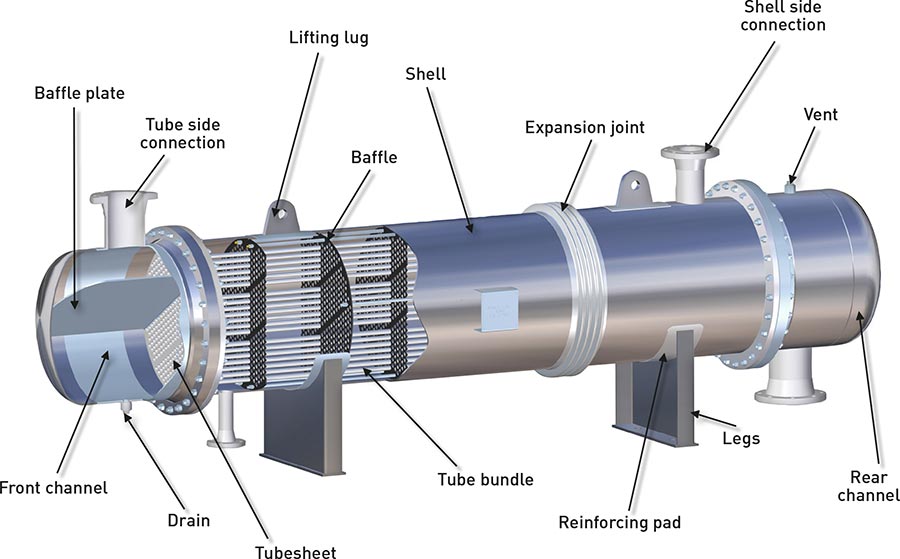

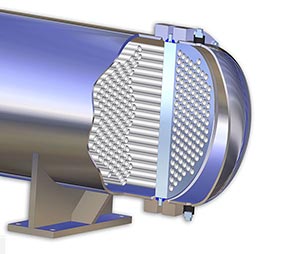

A typical schematic of a shell & tube heat exchanger, also called multitubular heat exchanger, shown below. This type of heat exchanger consists of a tube bundle inserted inside a shell. One of the fluids circulates inside the tubes and the other around them inside the shell. The number of baffles and their geometry are optimized in order to improve the heat transfer. Front and rear channels are attached at each end of the bundle, ensuring the distribution of the fluid inside the tubes. Their configuration may be for one or more passes in order to control the fluid velocity inside the tubes. In the shell side, the fluid circulates outside the tube bundle along the path imposed by the baffles. The diameter of the tubes is also optimized depending on the nature and quality of the fluid.

OPTIONS AND CONFIGURATIONS

The main advantage of the shell and tube technology is to offer a wide range of configurations to meet your expectations. The operational constraints of the process are taken into account by our engineering team, highly specialized in thermal and mechanics, in order to propose the right heat exchanger configuration.

CONFIGURATION EXAMPLES

- Vertical or horizontal

- In series, in parallel and/or stacked

- Fixed of floating tubesheet

- Custom made connections, flanges, lifts and supports

TUBES-TO-TUBESHEET WELDED JUNCTIONS

Generally, the connection of the tubes to the tubesheet is ensured by a roll expansion (mechanical seal) of the tube ends. The use of single or double grooves in the tubesheet holes also ensures an excellent bond as tight and durable as a weld. In some processes where temperatures are high, the roll expansion is completed by a seal weld. Other applications may also require a strength weld to reinforce the tubes-to-tubesheet junction.

USE OF LOW FINS

In some cases, low fin or grooved tubes are used to increase the turbulences or the exchange surface, significantly reducing the size of the exchanger.

THE 3 MAIN FAMILIES OF SHELL & TUBE

The different designs of shell and tube heat exchangers can be grouped under 3 main families

SHELL & TUBE WITH FIXED TUBESHEET

Straight tube ends are connected to the tubesheets, which are welded to the shell. This configuration of shell & tube heat exchangers is very competitive and offers the possibility of mechanically cleaning the inside of the tubes since the water box covers are removable. On the other hand, since the tubesheet are welded to the shell, there is no access to mechanicaly clean the tube bundle; only chemical cleaning in place (ClP) is possible. Furthermore, if the shell and tube exchanger is subjected to high temperature variations, it must be equipped with an expansion joint to absorb thermal expansion of the tubes.

SHELL & TUBE WITH FLOATING TUBESHEET

This technology does not require an expansion joint since one of the tube sheets is floating. Most of the time, the tube bundle can be removed from the shell, which allows mechanical cleaning of the external surface of the tubes as well as the inside surface of the shell. In addition, the tube bundle can be replaced more easily if needed.

SHELL & TUBE WITH U TUBES

The U-tube configuration avoids the use of expansion joints since the opposite tube end (U-bended) is free to move (not connected to a tubesheet). On the other hand, mechanical cleaning of the inside of the tubes becomes difficult due to the U-shape of the tubes. However, this shell and tube heat exchangers configuration is relatively inexpensive since it avoids the use of a second tubesheet.

LEAK DETECTORS

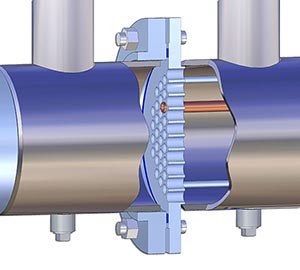

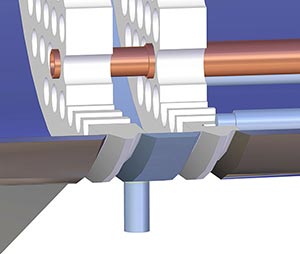

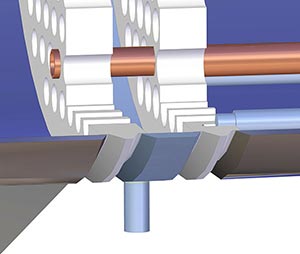

SHELL & TUBE WITH DOUBLE TUBE LEAK DETECTOR

This shell & tube configuration is based on the insertion of a tube inside a second tube of a larger diameter. In the event of a leak from the inner tube where the fluid circulates, longitudinal grooves situated between the two tubes permit the transport of the leaking fluid to a detection compartment. It may then trigger an alarm or accumulate in a leak reservoir, thus preventing fluid contamination or liquid splashing onto sensitive surrounding equipments.

SHELL & TUBE WITH DOUBLE TUBESHEET LEAK DETECTOR

Statistically, most leaks occur near or at the tube to tube plate (tubesheet) joint, the location where the material must withstand the greatest stress concentrations from thermal expansion, roller expansion or tube joint welds. This second technology option is less expensive than the previous and allows, by the addition of a second tube plate, the transport of the fluid leaking through a non functional tube to tube plate joint into a detection chamber.

FIELDS

- Petrochemicals

- Power generation plants

- Pulp & Papers

- District cooling & heating

- Marine

- Steam & Gas turbines

APPLICATIONS

- Heating/cooling of gaseous or liquid fluids

- Boilers

- Crude oil preheater

- Black liquor heater

- White water heat recovery unit

- Steam condenser

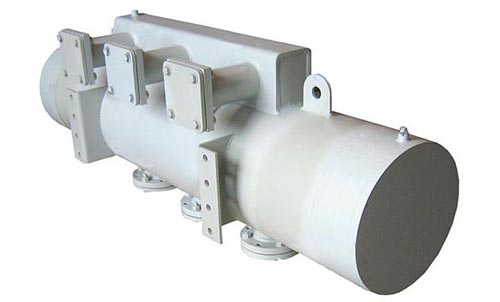

- OFWF & ONWF Transformer oil coolers

A WIDE CHOICE OF MATERIALS

TUBES

- Steel

- Stainless Steel (304,316L, etc.)

- Brass

- Cu-Ni 90/10

- Cu-Ni 70-30

- Titanium

- Copper

- Monel

- Inconel

SHELL

- Steel

- Stainless steel (304,316L, etc.)

- Aluminium

- Monel

TUBESHEET

- Steel

- Stainless steel (304,316L, etc.)

- Naval Brass

- Aluminium

- Cu-Ni 90/10

- Cu-Ni 70-30

- Titanium

- Monel

Thanks to its qualified welders, Thermofin is able to manufacture shell and tube heat exchangers with many other exotic materials compatible with your process. Our quality system guarantees a perfect traceability of the materials used to make your exchanger. A copy of the material mil test certificates can also be provided upon request.

HIGH QUALITY STANDARDS

In addition to the ISO 9001 standards, Thermofin’s shell & tube heat exchangers may be designed to meet the prescriptions of TEMA specifications. Thermofin’s unit may bear the ASME “U” or “UM” Stamp, the China Licence number (Cat II pressure vessel), or they may also be registered with quality control agencies such as the American Bureau of Shipping (ABS), the National Board (NB), the American petroleum institute (API) and other regional jurisdictions (CRN, CSA B51). All CALEOS shell & tube heat exchangers are manufactured following a dedicated inspection and test plan (ITP) which can be provided prior to manufacturing.

OTHER SERVICES

In addition to the designing & manufacturing of shell & tube heat exchangers, Thermofin offers cleaning, reconditionning, retubing and reverse engenieering services. Thanks to our ultra-dynamic team, we offer a complete retubing service of any brand of exchangers within a period as short as one weekend. In addition, Thermofin holds the R stamp to modify or repair exchangers registered with the National Board.

You are an agent interested in selling our products, or you are simply looking for additional information? Don’t hesitate to download our brochures. We can also provide, upon request, prints & other promotional material.