FURTHER TOGETHER... IN ELECTRICAL SUBSTATIONS

Electric substations are critical parts in the electricity transmission and distribution network. Power substations are used, among other things, to convert the voltage of the distribution network (high voltage to low voltage or vice versa) through the use of transformers, but also to change the type of current (direct current to alternating current or vice versa).

Current conversion (high voltage – low voltage, AC / DC) generates a large number of thermal losses which have to be evacuated by the use of coolers. These heat losses come from the very heart of transformers, but also from external components such as thyristor valves used in high voltage direct current (HVDC) converters.

Given the critical importance of power substations in the transmission and distribution network, transformer coolers as well as HVDC coolers must not only have a robust construction, but also be designed to minimize downtime during maintenance. In addition, many substations are monitored remotely which requires increased reliability of transformer coolers.

A FULL RANGE OF TRANSFORMER COOLERS

No matter the type of cooler you are looking for, Thermofin is able to customly design your transformer cooler in order to meet your dimensional constraints.

OFAF (Oil Forced Air Forced) transformer cooler

Thanks to the fans, these coolers use ambient air to cool down the dielectric oil contained in the transformers. OFAF coolers are often used when the cooling capacities are pretty high.

ONAN (Oil Natural Air Natural) transformer cooler

ONAN (Oil Natural / Air Natural) transformer coolers, also known as panel radiators, use free convection (no fans) on the air side to cool the dielectric oil contained in the transformers. The circulation of the oil in the ONAN exchanger is also carried out in natural convection (by thermosiphon). It is therefore not necessary to use an oil-side circulation pump. ONAN coolers are often used when the cooling capacities are low. Thanks to the pannel technology, these coolers offer a high reliability combined to a low cost.

ONAF (Oil Natural Air Forced) transformer cooler

ONAF (Oil Natural / Air Forced) transformer coolers are in fact ventilated panel radiators. The addition of fans significantly increases the panel radiator efficiency by changing the operating mode from free convection to forced convection.

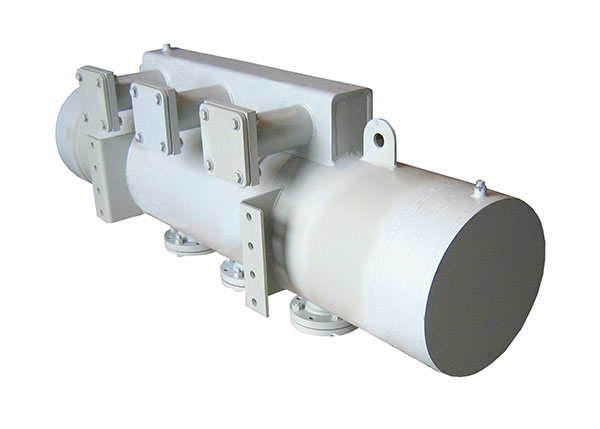

OFWF (Oil Forced Water Forced) transformer cooler

In electrical substations close to hydroelectric dams, water can be used, instead of air, to cool down transformers. Thus, the dielectric oil contained in transformers is cooled with raw water coming from a river or a nearby lake. By using water, OFWF transformer coolers are able to evacuate large quantities of heat while offering a small footprint.

ONWF (Oil Natural Water Forced) transformer cooler

As with the OFWF transformer coolers, water is used to cool the transformer dielectric oil. On the other hand, these transformer coolers are designed in natural convection on the oil side, so it is not necessary to use an oil pump, the oil flowing naturally by thermosiphon in the exchanger.